At ABIS International, we do more than design factory layouts; we engineer high-performance manufacturing environments tailored for the modern cable industry.

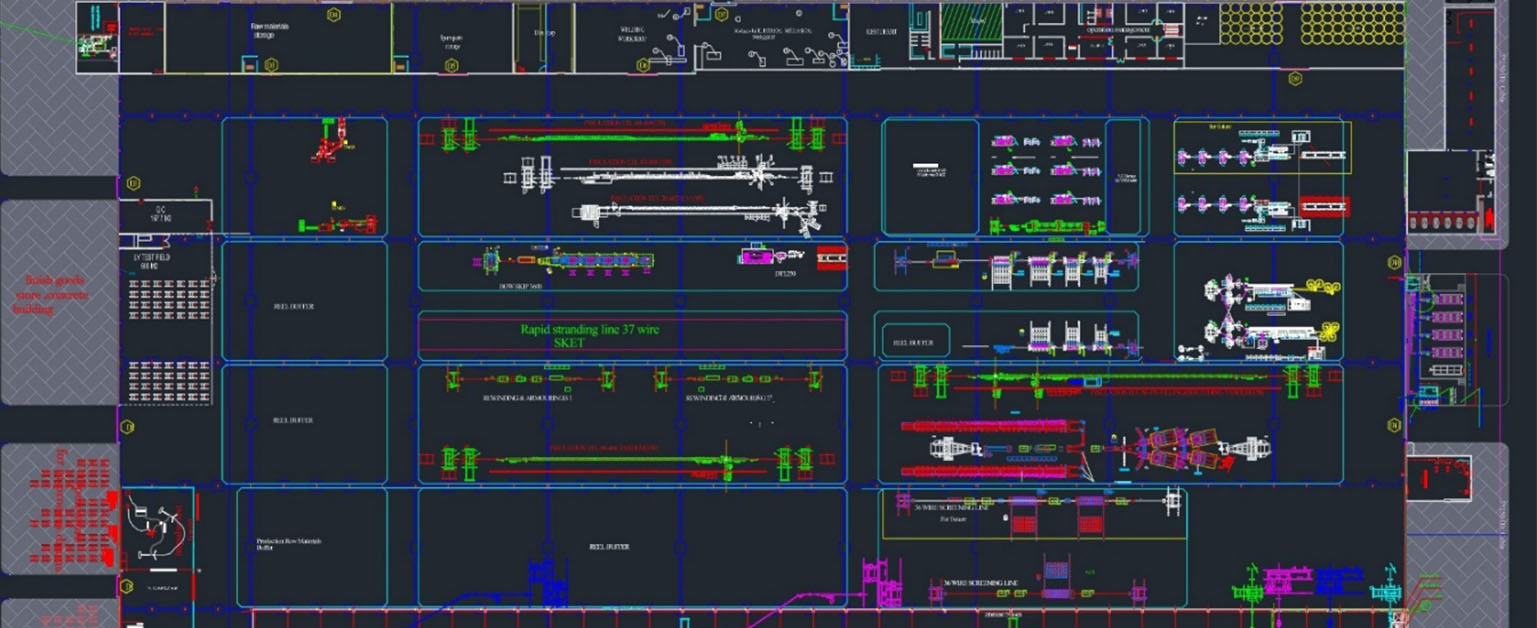

Our team conducted a full-cycle analysis of the cable production process to design a linear plant layout that enables continuous, interruption-free operations.

The result: smarter movement, reduced waste, and faster throughput.

Where Function Meets Form. To ensure maximum safety, flow, and space utilisation, the facility was divided into clearly defined operational zones:

We collaborated closely with MEP and facility engineering teams to embed essential utility systems into the layout itself, including:

These systems were designed for optimal performance, easy access, and zero disruption to manufacturing activities.

Built with long-term success in mind, the facility features modular expansion zones that support:

This forward-thinking approach ensures that the plant grows without disrupting existing operations.

We engineer facilities that support not just machines—but the people who run them. Every element of the layout prioritises operator safety, comfort, and efficiency:

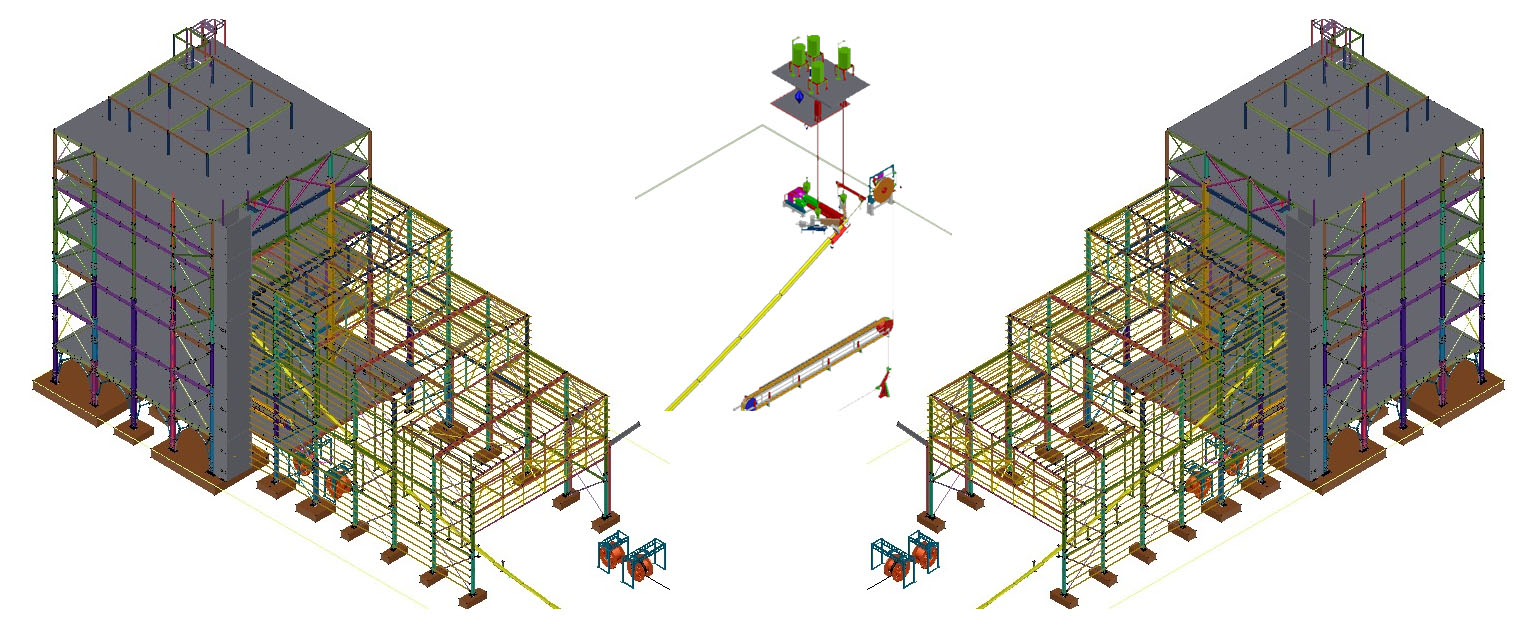

At ABIS International, we specialise in the custom design and engineering of Catenary Continuous Vulcanisation (CCV) lines for the cable manufacturing industry.

Our solutions are tailored for high-performance cable production lines, meeting the rigorous demands of today’s medium voltage (MV) and extra-high voltage (EHV) cable systems.

We go beyond standard layouts. Each CCV system we engineer is custom-built for your facility and production goals:

Our custom CCV systems are ideal for a range of cable manufacturing applications, including:

Clients using ABIS-engineered CCV lines for cable production benefit from:

Whether you are upgrading an existing plant or developing a new cable manufacturing facility, our engineering team is ready to design a scalable, efficient CCV layout that accelerates your production.

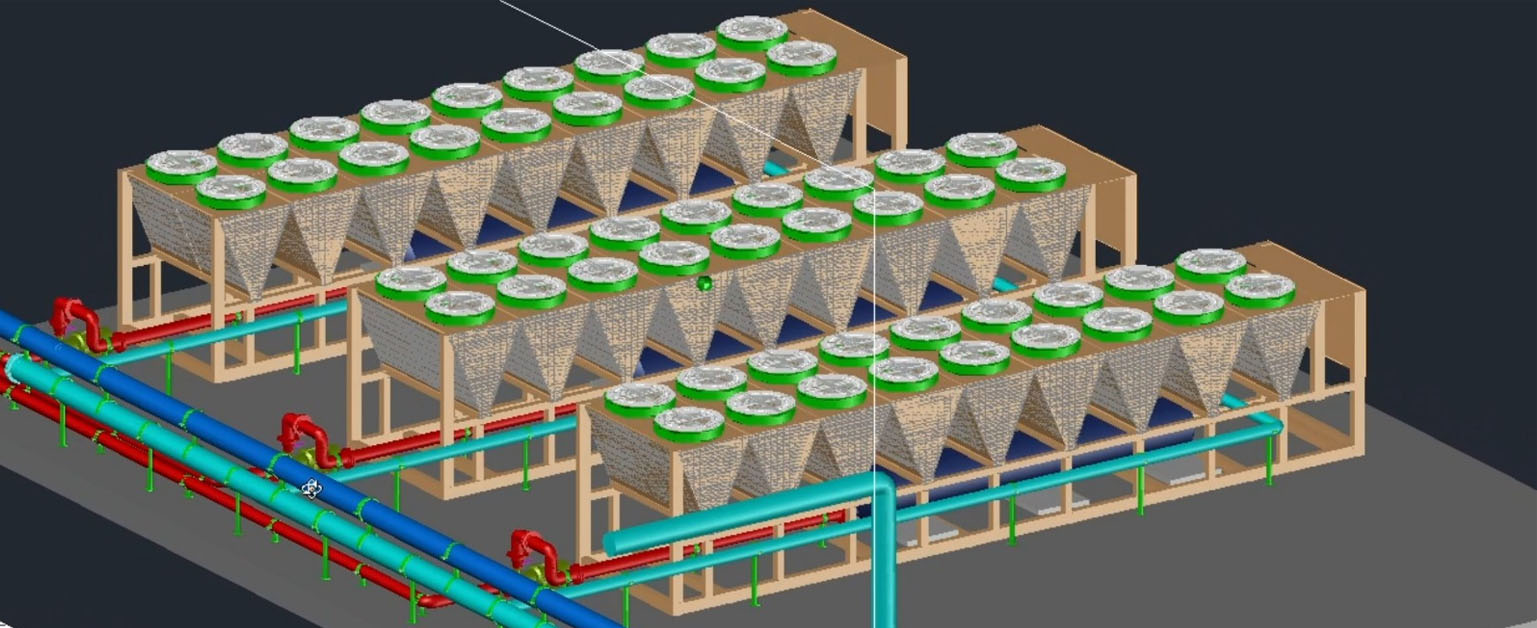

Our Utilities Engineering Design Service covers every critical infrastructure system that powers your plant, including:

At ABIS International, we specialise in the design of Utilities Engineering Networks for factories, from cable manufacturing plants to a wide range of industrial facilities.

Our approach ensures efficient, reliable, and safe distribution of essential services like compressed air, chilled water, steam, and electrical power.

ABIS specialises in designing and implementing corrosion-resistant compressed air networks for factories that utilise pneumatic systems.

Additionally, ABIS will create and install a ventilation system for compressors, complete with air dryers.

This system includes moisture and impurity filtering and purification units for compressed air, ensuring the pneumatic network is protected from damage and malfunction.

ABIS engineers are prepared to conduct comprehensive studies, design, and implement chilled water system networks for factories and other establishments that require cold water.

This includes the development of heat exchanger networks designed to cool products or the surrounding environment.

ABIS offers a comprehensive study, design, implementation, and commissioning of industrial boiler distribution networks that supply factories and industrial establishments with the necessary hot water and steam.

At ABIS, we are dedicated to conducting comprehensive studies, designing, and implementing overhead cable trays and low-voltage networks for factories.

We carefully consider the detailed calculations of the cables used and the electrical loads of the machines and facilities.

Ensuring Precision in Cable Extrusion

Air vacuum systems are essential in cable extrusion lines to maintain uniform insulation thickness and eliminate air bubbles during sheath application.

Applications include:

Cooling & Temperature Control for Reliable Production

Process water is one of the most vital utilities in a cable factory, primarily used in cooling troughs and water baths during cable extrusion.

Applications include:

Powering Heavy-Duty Cable Manufacturing Equipment

Hydraulic systems are the backbone of many mechanical operations within a cable factory. They provide the force needed for:

Benefits of hydraulic systems in cable factories:

Cable factories face unique fire risks due to the presence of flammable materials such as PVC, polyethene, insulation compounds, lubricants, and packaging.

High heat from extrusion machines, electrical faults, and dust accumulation can rapidly escalate into dangerous fires if not managed effectively.

A well-designed combination of air vacuum, process water, and hydraulic systems ensures:

We specialize in the design, installation, and maintenance of utility systems tailored to cable manufacturing operations.

Our solutions are engineered for efficiency, reliability, and scalability, helping you achieve world-class production standards.